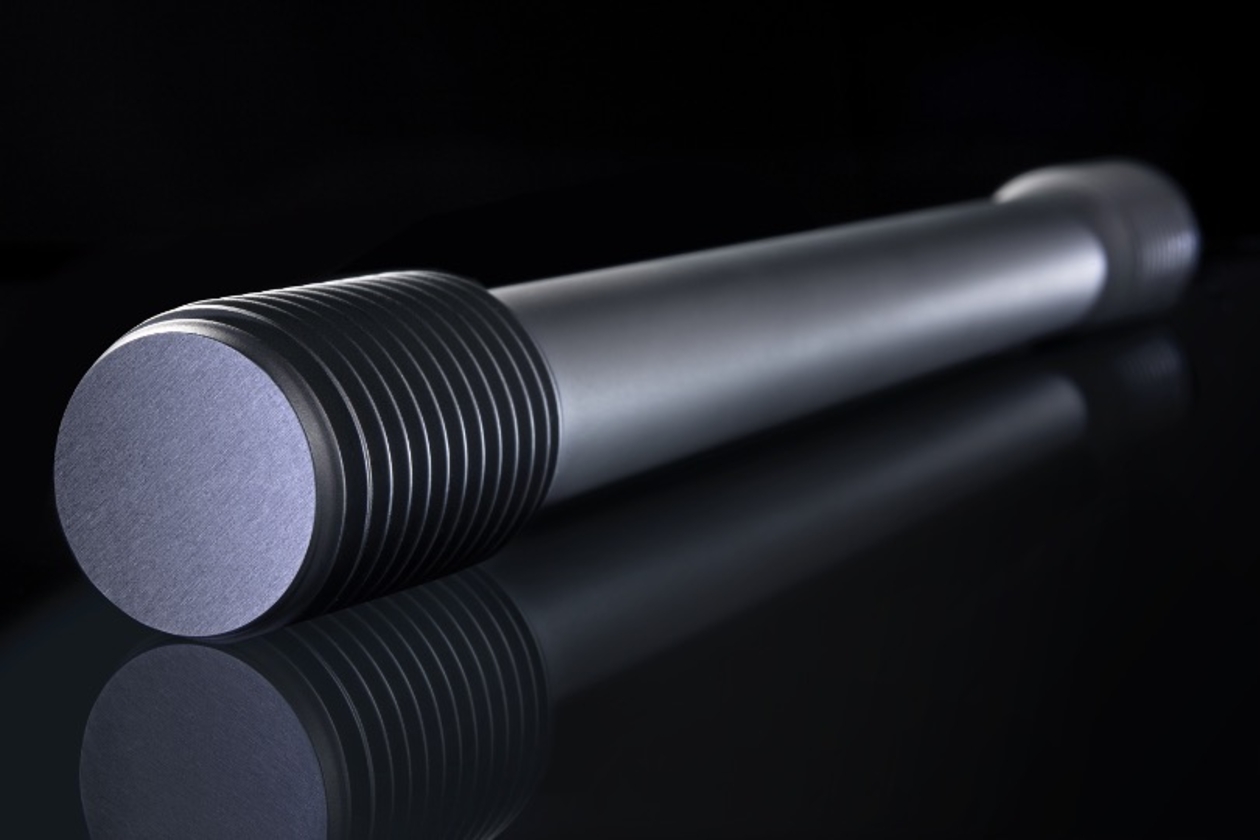

What is a zinc flake?

A zinc lamella is a corrosion protection coating composed of zinc and aluminum. This compound is held together by an inorganic matrix. If a coating of zinc flakes is applied to a component, this layer shields the metal from external influences.

When applied correctly and over the entire surface, such a zinc flake coating provides durable and long-lasting protection against corrosion even at low coating thicknesses.

How does a zinc flake coating work?

The zinc flake coating acts like a protective layer between metal/steel and the environment. The zinc portion of the coating acts here as active, cathodic corrosion protection - the zinc "sacrifices" itself and is gradually removed over time by environmental influences. However, the metal underneath the zinc flake coating is not affected by these processes. By completely isolating the metal/steel from the environment, the coated object permanently retains its properties without being affected by corrosive influences.

Why do I need a zinc flake coating?

A professionally applied zinc flake coating prevents the respective metal parts from being exposed to the environmental influences around them without protection. This brings with it a number of advantages:

- Longer durability of the components

- High corrosion protection

- Flawless optics throughout

- Lower maintenance costs

The use of a zinc flake coating thus helps to reduce corrosion-related damage to components to a minimum. This makes structures more durable and significantly reduces the financial costs of refurbishment measures.

In which areas are zinc flake coatings used?

Zinc flake coatings have already established themselves as popular corrosion protection solutions in numerous industries. For example, they are used in the following industries:

- Automotive industry

- Agricultural machinery

- Construction machinery

- Renewable energy (wind parks)

These are just some of the most prominent industries - a zinc flake coating can be used almost universally thanks to its practical properties. We would also be happy to advise you on your application options.

How can a zinc flake coating be applied?

There are various processes for applying a zinc flake coating to components. These include the spray process, the dip-spinning process, the rack-dip-spinning process and the dip-drawing process. Which zinc flake coating process is used in each case depends on both the number of components and their size. For example, the dip-spin process is typically used for bulk material, but larger components are usually treated by the spray process.

Belgium nederlands

Belgium nederlands Belgium français

Belgium français Canada english

Canada english Canada français

Canada français China chinese

China chinese Czech Republic čeština

Czech Republic čeština Deutschland deutsch

Deutschland deutsch France français

France français Hungary magyar

Hungary magyar International english

International english Italy italiano

Italy italiano Netherlands nederlands

Netherlands nederlands Poland polski

Poland polski Russia русский

Russia русский Slovakia slovenčina

Slovakia slovenčina Switzerland français

Switzerland français Switzerland deutsch

Switzerland deutsch Turkey Türkçe

Turkey Türkçe USA english

USA english