Corrosion Expert Florian Feldmann, Product Engineer at Dörken, tells us the significance of the test variants for material manufacturers and how they are implemented in day-to-day operations.

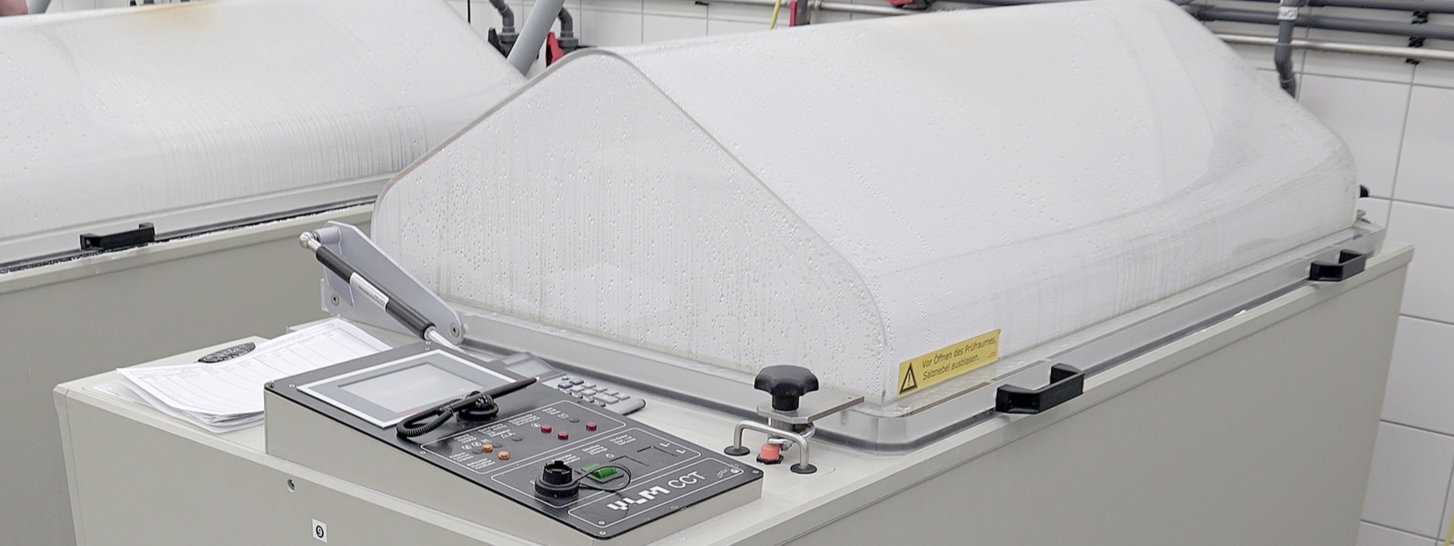

What corrosion tests are carried out at Dörken?Florian Feldmann: To reflect as great a variance of environmental stresses as possible, we conduct both short-term laboratory tests and long-term tests in the form of outdoor weathering studies. The short-term tests include, for example, salt spray testing according to DIN EN ISO 9227 and condensation testing as per DIN EN ISO 6270-2. Both of these are constant climate tests, but with different corrosive atmospheres. In addition, we also conduct a large number of climatic extremes tests for various car makers. In the area of long-term tests Dörken – often in collaboration with diverse universities – is currently conducting outdoor weathering studies on Heligoland, on the FINO II offshore platform in the Baltic, in Vienna, in Palavas (France) and also in Herdecke, near the company headquarters.

What components do you test at Dörken?Florian Feldmann: It varies: we test standard parts, but also special customer parts. These range from tiny screws to sheet metal and on to large components from diverse branches with diverse corrosion requirements. We coat the parts beforehand with various Dörken coating systems as well as reference systems. In addition, we also apply a mechanical stress to most, such as a crack or a stone impact, or subject them to thermal pre-stress to simulate corrosion behaviour in parts that are already damaged. Pre-stressing gives us a highly complex overall image of the corrosion behaviour of the surface. (Photo) documentation occurs at regular intervals, together with evaluation of the findings of the test series.

Are the same parts always subjected to outdoor weathering?

Florian Feldmann: Not as a rule. However, we have started a test series in which the same parts are exposed on the FINO II in the Baltic, in Vienna, Herdecke and France. Different climates result in different forms of corrosion. This test series therefore provides an excellent opportunity to compare corrosion behaviour under different climatic conditions: How does the surface of a part react to a more rural environment in Herdecke compared to a big city like Vienna, to the maritime climate on Heligoland, or the warm maritime climate in southern France?

Belgium nederlands

Belgium nederlands Belgium français

Belgium français Canada english

Canada english Canada français

Canada français China chinese

China chinese Czech Republic čeština

Czech Republic čeština Deutschland deutsch

Deutschland deutsch France français

France français Hungary magyar

Hungary magyar International english

International english Italy italiano

Italy italiano Netherlands nederlands

Netherlands nederlands Poland polski

Poland polski Russia русский

Russia русский Slovakia slovenčina

Slovakia slovenčina Switzerland français

Switzerland français Switzerland deutsch

Switzerland deutsch Turkey Türkçe

Turkey Türkçe USA english

USA english